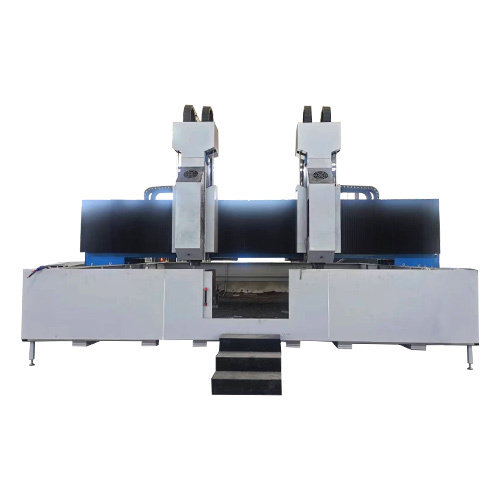

TLMZ series(Moving column) drilling milling machine

WhatsApp:

Email:

Product Details

Product Description:

TLMZ series(Moving column)drilling and milling machine adopts the method of moving the gantry while the worktable is fixed. The gantry moves in the X direction on the bed, the sliding pillow drilling power head moves in the Y direction on the crossbeam, and the spindle and sliding pillow move in the Z direction on the slide seat.

This machine tool uses a digital control system, which is very convenient to operate and can achieve automation, high precision, multiple varieties, and mass production. This machine tool is mainly used for drilling and milling of flat parts such as flat plates, flanges, discs, rings, etc.

Product performance:

1.This machine tool is equipped with a tool wear monitoring function (Patent number: ZL2013 2 0746891.6), which displays tool wear in real-time during high-speed machining, facilitating timely tool replacement and effectively preventing the occurrence of blade breakage and other situations caused by blade wear.

2.This machine tool has added a separate accumulator to the balance cylinder, (Patent number: ZL2013 2 0747230.5); The purpose is to prevent damage to the motor due to stuck valves or other unexpected situations that may cause the oil in the cylinder to have nowhere to drain. After adding an accumulator, the oil in the cylinder can flow back to the accumulator, which also provides protection for the hydraulic cylinder.

3.To ensure stability during the machining process, this machine tool has added a hydraulic clamping device(Patent number ZL2013 2 0747230.5); The gantry moves in the X-direction on the bed, and during drilling, the hydraulic cylinder on the bed holds the gantry tightly against the bed, preventing it from moving relative to each other; The skateboard moves in the Y direction on the crossbeam, and during drilling, the hydraulic cylinder on the crossbeam clamps the skateboard and crossbeam to prevent them from moving relative to each other.

4.The main components of this machine tool, such as the bed, worktable, sliding pillow, crossbeam, etc., are all cast in a box or similar box shape. The gantry adopts a high-strength welding structure, and the entire machine has sufficient strength, rigidity, and stability. The outer surface of large components such as crossbeams and sleepers is machined and repaired to ensure a smooth surface and beautiful overall appearance.

5.This machine tool adopts precision drilling and milling spindles from world-renowned brands, which have the best spindle accuracy and are particularly suitable for drilling. Its spindle operates more smoothly, has lower noise, and has a longer service life.

6.The spindle is equipped with an automatic tool locking device. The tool clamping force is strong and the tool change is fast, ensuring the safety and reliability of clamping or unclamping the tool.

7.To meet the processing needs of deep hole workpieces, the spindle of this machine tool is equipped with an internal water outlet system.A splash protection cover is specifically installed at the lower end of the slider.

8.The X-axis, Y-axis, and Z-axis are all guided by wide heavy-duty linear rolling guide rails. The linear guide rails have high motion sensitivity and operating accuracy, and strong load-bearing capacity. This combination of guide rails improves the accuracy stability of the machine tool and extends its service life.

Product Parameters:

| Prameter | Description | Unit | TLMZ2020 | TLMZ2525 | TLMZ3030 | TLMZ4040/2 | TLMZ5050/2 | TLMZ6060/2 | TLMZ7070/2 | TLMZ8080/2 | TLMZ9090/2 | TLMZ100100/2 | TLMZ110110/2 | TLMZ120120/2 |

| Processing range | Length×Width | mm | 2000X2000 | 2500×2500 | 3000×3000 | 4000×4000 | 5000×5000 | 6000×6000 | 7000×7000 | 8000×8000 | 9000×9000 | 10000×10000 | 11000×11000 | 12000×12000 |

| Gantry span | Width | mm | 2800 | 3300 | 3800 | 4800 | 5800 | 6800 | 7800 | 8800 | 9800 | 11000 | 12000 | 13000 |

| T-slot | Width | mm | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 |

| Power Head | Number | Piece | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Spindle taper hole | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | BT50(With torque overload protection) | ||

| Maximum drilling diameter | mm | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | |

| Spindle speed range | rpm/min | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | 5-4500 | |

| Spindle motor power | KW | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | |

| Distance from spindle end face to worktable | mm | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | 300-1100 | |

| Longitudinal movement of gantry (X-axis) | Travel | mm | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 | 11000 | 12000 |

| Maximum movement speed | m/min | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| Motor power/torque | KW/N.m | 2*2.2/11 | 2 X 2.2/11 | 2 X 2.2/11 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 7.7/48 | 2 X 7.7/48 | 2 X 7.7/48 | 2 X 7.7/48 | |

| Spindle lateral movement(Y-axis) | Travel | mm | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 | 11000 | 12000 |

| Maximum movement speed | m/min | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| Motor power/torque | KW/N.m | 2.2/11 | 2.2/11 | 2.2/11 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 5.2/36 | 2 X 5.2/36 | 2 X 5.2/36 | 2 X 5.2/36 | |

| Spindle vertical feed (Z -axis) | Travel | mm | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Maximum feed speed | m/min | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Motor power/torque | KW/N.m | 3.0/16 | 3.0/16 | 3.0/16 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 3.0/19 | 2 X 5.2/36 | 2 X 5.2/36 | 2 X 5.2/36 | 2 X 5.2/36 | |

| Positioning accuracy | X-axis | mm | 0.05 | 0.05 | 0.05 | 0.06 | 0.06 | 0.08 | 0.12 | 0.12 | 0.12 | 0.12 | 0.16 | 0.18 |

| Y-axis | mm | 0.05 | 0.05 | 0.05 | 0.06 | 0.06 | 0.08 | 0.12 | 0.12 | 0.12 | 0.12 | 0.16 | 0.18 | |

| Repeatability | X-axis | mm | 0.025 | 0.025 | 0.025 | 0.03 | 0.03 | 0.04 | 0.06 | 0.06 | 0.06 | 0.06 | 0.08 | 0.08 |

| Y-axis | mm | 0.025 | 0.025 | 0.025 | 0.03 | 0.03 | 0.04 | 0.06 | 0.06 | 0.06 | 0.06 | 0.08 | 0.08 | |

| Chip removal system | Chip conveyor form | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | |

| Number | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Chip removal speed | m/min | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Chip conveyor motor power | KW | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | 2X0.75 | |

| High pressure internal cooling | Pressure/Flow/Power | Mpa/L/min/KW | 5/40/5.5 | 5/40/5.5 | 5/40/5.5 | 5/40/5.5 X 2 | 5/40/5.5 X 2 | 5/40/5.5 X 2 | 5/40/5.5 X 2 | 5/40/5.5 X 2 | 5/40/5.5 X 2 | 5/40/5.5 X 2 | 5/40/5.5 X 2 | 5/40/5.5 X 2 |

| Low pressure external cooling | Pressure/Flow/Power | Mpa/L/min/KW | 0.2/30/0.2 | 0.2/30/0.2 | 0.2/30/0.2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 | 0.2/30/0.2X 2 |

| Hydraulic system | Pressure/Flow/Power | Mpa/L/min/KW | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 | 7/30/4 |

| Automatic lubrication system | Lubrication pressure | Mpa | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Lubricating point oil filling amount | mL/time | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | |

| Oil filling cycle | min | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | |

| electrical system | CNC system | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | |

| Number of CNC axes | 4+1 | 4+1 | 4+1 | 6+2 | 6+2 | 6+2 | 6+2 | 6+2 | 6+2 | 6+2 | 6+2 | 6+2 | ||

| Power and weight | Total power | KW | 55 | 55 | 55 | 110 | 110 | 110 | 110 | 110 | 125 | 125 | 125 | 125 |

| Total weight | T | 20 | 30 | 40 | 55 | 60 | 80 | 100 | 140 | 180 | 220 | 250 | 280 | |

| Dimensions | Length×Width×Height | mm | 5000×4600×3000 | 5500×5100×3000 | 6000×5500×3000 | 8200×7900×4500 | 9200×8900×4500 | 10200×9900×4500 | 11200×11000×4500 | 12200×12000×4500 | 13200×13000×4500 | 14200×14000×4500 | 15200×15000×4500 | 16200×16000×4500 |

FACTORY ENVIRONMENT

HONOR

RELATED PRODUCTS

FAQ

Q:How do you make our business long-term and good relationship?

A:We keep good quality and competitive price to ensure our customers benefit ; We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from

Q:How can i get the price?

A:We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q:What services can we provide?

A:Accepted Delivery Terms: CIF,FAS,Express Delivery; Accepted Payment Currency:USD; Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow; Language Spoken:Chinese,Spanish,Japanese,Portuguese,German,Arabic,Russian,Korean,Hindi,Italian

Q:Why should you buy from us not from other suppliers?

A:Whether you are selecting the current product from our production catalog or seeking help for your personalized application, you can discuss with us and get satisfactory answers.

Q:What can you buy from us?

A:Vertical drilling machines, CNC lathes, ordinary lathes, metal band sawing machines, drilling and milling machines, milling machines, grinding machines, slotting machines, shapers, hydraulic machines, air hammers, horizontal machining centers, vertical machining centers, industry specialized machines, economical CNC machine tools, and ordinary machine tools, totaling more than 20 categories, more than 50 series, and more than 200 products

Q:How can we guarantee quality?

A:Always a pre-production sample before mass production; Always final Inspection before shipment;

Q:How to choose the most suitable machine?

A:Tell us your processing requirements and specifications, and we will choose the most suitable model for you. You can also send us product drawings or customize according to your requirements.

Q:Can I buy samples placing orders?

A:Yes.Please feel free to contact us.

MESSAGE