TCK series single column lathe

WhatsApp:

Email:

Product Details

Product Description:

TCK series single column vertical lathe is suitable for high-speed steel cutting tools, carbide cutting tools and various high-performance cutting tools. It can process ferrous metals, non-ferrous metals and some non-metallic materials.On machine tools, they can complete fine machining of inner and outer cylindrical surfaces, inner and outer conical surfaces, flat surfaces, rotary surfaces, and grooves.The spindle is equipped with an encoder to achieve the function of turning threads.

product performance:

1.The machine tool slide is made of MTCrCu300 alloy cast iron, which has good toughness.

2.The machine tool castings are all made of HT250 cast iron, which has been artificially heat aged and will not deform.

3.The rough surfaces of large castings such as columns, beams, and rotary slides seats are scraped flat with a cutting tool to ensure that the surface is smooth and free of debris.

4.The guide rail surface of the column and crossbeam is quenched using ultrasonic frequency, and the quenched guide rail surface can be maintained without damage for decades.

5.The base guide rail is inlaid with zinc-aluminum alloy plate, which is wear-resistant and durable.

6.The gearbox and main motor are equipped with protective covers. The main motor protective cover adopts double-door type, which is safe, user-friendly and easy to maintain.

7.All lubrication systems are supplied with regular and quantitative oil by automatic oil supply pumps.

8.The processing and assembly of machine tool parts are manufactured according to European and American standards.

Product Parameters:

| Prameter | Unit | TCK5116 | TCK5120 |

| Maximum turning and cutting diameter | mm | 1600 | 2000 |

| Workbench diameter | mm | 1400 | 1800 |

| Maximum workpiece height | mm | 1400 | 1400 |

| Maximum workpiece weight | t | 5 | 8 |

| Maximum torque of workbench | KN.m | 40 | 40 |

| Workbench speed range | r/min | 4-125 | 4-125 |

| Sliding pillow section | mm | 200x200 | 200x200 |

| Maximum cutting force of vertical tool holder | KN | 22 | 22 |

| Tool holder feed range | mm/min | 0.1-500 | 0.1-500 |

| Vertical tool holder horizontal stroke | mm | -50-850 | -50-1050 |

| Vertical tool holder sliding pillow stroke | mm | 800 | 800 |

| Tool holder rapid movement speed | mm/min | 2000 | 2000 |

| Tool holder cross-sectional dimensions (Width × Height) | mm | 30×40 | 30×40 |

| Main motor power | KW | 45 | 45 |

| Electrical system | Spindle installation encoder | Spindle installation encoder | |

| Dimensions(Length×Width×Height) | mm | 2400×2300×3100 | 2800×2700×3100 |

| Weight | T | 14 | 17.5 |

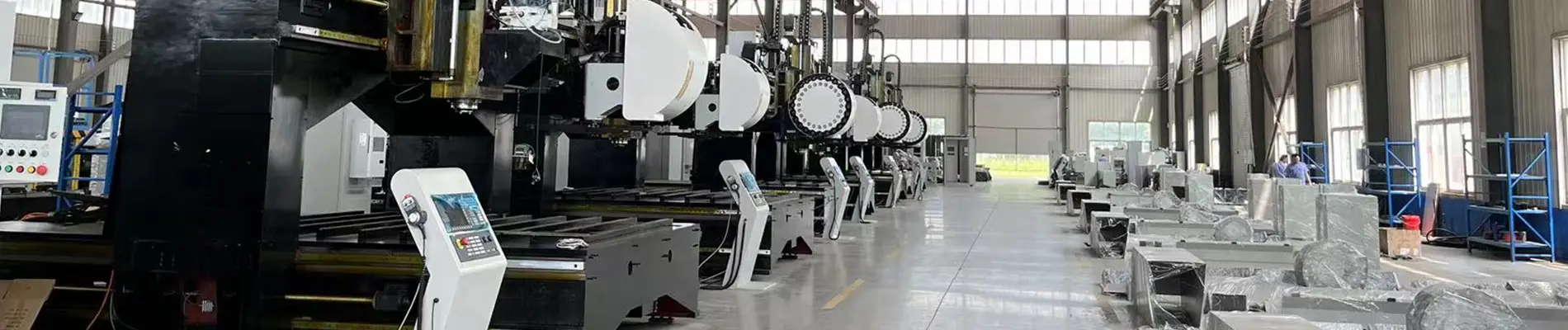

FACTORY ENVIRONMENT

HONOR

RELATED PRODUCTS

FAQ

Q:How do you make our business long-term and good relationship?

A:We keep good quality and competitive price to ensure our customers benefit ; We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from

Q:How can i get the price?

A:We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q:What services can we provide?

A:Accepted Delivery Terms: CIF,FAS,Express Delivery; Accepted Payment Currency:USD; Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow; Language Spoken:Chinese,Spanish,Japanese,Portuguese,German,Arabic,Russian,Korean,Hindi,Italian

Q:Why should you buy from us not from other suppliers?

A:Whether you are selecting the current product from our production catalog or seeking help for your personalized application, you can discuss with us and get satisfactory answers.

Q:What can you buy from us?

A:Vertical drilling machines, CNC lathes, ordinary lathes, metal band sawing machines, drilling and milling machines, milling machines, grinding machines, slotting machines, shapers, hydraulic machines, air hammers, horizontal machining centers, vertical machining centers, industry specialized machines, economical CNC machine tools, and ordinary machine tools, totaling more than 20 categories, more than 50 series, and more than 200 products

Q:How can we guarantee quality?

A:Always a pre-production sample before mass production; Always final Inspection before shipment;

Q:How to choose the most suitable machine?

A:Tell us your processing requirements and specifications, and we will choose the most suitable model for you. You can also send us product drawings or customize according to your requirements.

Q:Can I buy samples placing orders?

A:Yes.Please feel free to contact us.

MESSAGE